Download Printer Friendly PDF Version

|

pH / ORP / ISE Process Measurement & Control Systems |

|

Case Study # 2 – High Sulfide Process Media- (January 2004) |

|

Features · Guaranteed Longest Lasting Sensors Available with performance guarantee *

· Sensors are compatible with most existing pH/ORP Meters, Transmitters & Analyzers **

· Application Specific Engineering results in optimum Lifetime & Performance ***

· Integrated Temperature Compensation, Preamplifiers & Solution Ground Elements

· Solid State Reference System offers superior resistance to Fouling & Dehydration

· Applications such as Acid/Fluoride, Hi-Temp, Saturated Sodium and Sulfide Resistant are available as standard options

· Custom Applications are available, often at no additional charge

· Most Installation Styles are Supported Including: Immersion, Twist Lock, Valve Retractable & Sanitary

· Available in a wide range of plastics, from cost effective CPVC to thermally & chemically resilient ULTEM® and PEEK thermoplastic

· High Pressure Applications up to 100 psi for Valve Retractable & 150 psi for Inline Installations can be supported for continuous use

· Operating Temperatures from -30 to +150 ºC (-22 to +302 ºF) can be supported for continuous use |

Case Study No. 2 – High Sulfide, High pH Process Media

pH & ORP Measurement in High Sulfide, High Temperature and pH process solutions

The Problem

A catalyst manufacturer had a process requiring the removal of sulfides. The selected method of elimination was by stripping the sodium sulfide in a sodium hydroxide solution. The sodium sulfide concentration is controlled via a redox potential (ORP) measurement. In order to prevent free hydrogen sulfide gas from forming, the pH was kept at the maximum possible level (12 to 14.5). The problem having such a high pH solution was that it attacked the pH glass while the sulfide content entered the reference junction and destroyed the reference element causing premature sensor failure.

Similar side effects occurred when the pH drifted below 12, when hydrogen sulfide gas was produced. The gas then diffused through the reference junction into the sensor, destroying both the reference and pH components. The previously used sensors experienced corrosion problems, whereby sulfides would end the cable from the back side of the sensors, causing a sudden electrical short. The process conditions described manifested themselves in rapid sensor drift, frequent calibration and shortened sensor lifetime. The inaccuracy of the pH readings (particularly at very high pH) resulted in exceeding the emission limits, occasional emergency evacuations and EPA penalties.

The Solution

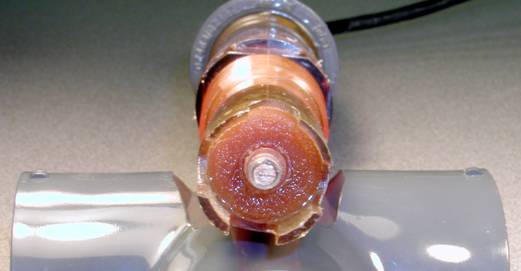

The solution was the combination of a high pH resistant pH and ORP glass elements sealed against sulfides together with a sulfide resistant solid state triple junction reference system. An ULTEM thermoplastic sensor body housing was chosen for its excellent chemical and thermal resistance to sulfides at a variety of pH and temperatures values. Waterproofing option “A” was installed on the sensors to make the assemblies suitable for completely submersible installation. The appropriate electronic components were integrated into these built to order (custom) pH and ORP sensors such that they could be installed on the existing pH and ORP transmitters. The result of using ASTI’s custom engineered pH and ORP sensors was to reduce the potential drift to a minimum and eliminate the need for frequent calibrations. The increased accuracy reduced the consumption of large quantities of chemicals and almost tripled the lifetime of the sensor, all with requiring the installation of new pH and ORP instrumentation.

The pH Sensor Used: Model: PNXTJ 6631-1000JYC-15 pH Sensor with Waterproofing Option “A” Description: ¾”- 1” MNPT Immersion ULTEM Bodied Sulfide Resistant pH Sensor with Triple Junction reference system; Accu-Temp Fast Response Integrated 1000 Ohm Platinum Temperature Element and Stainless Steel Solution Ground; 15 feet cable to connect directly to Johnson Yokogawa pH Analyzer/Transmitter – with Waterpoofing Option “A”

The ORP Sensor Used: Model: PNXTJ 6831/6631-1000JYC-15 ORP Sensor with Waterproofing Option “A” Description: ¾”- 1” MNPT Immersion ULTEM Bodied Sulfide Resistant ORP Sensor with Triple Junction reference system; Accu-Temp Fast Response Integrated 1000 Ohm Platinum Temperature Element and Stainless Steel Solution Ground; 15 feet cable to connect directly to Johnson Yokogawa pH Analyzer/Transmitter – with Waterpoofing Option “A”

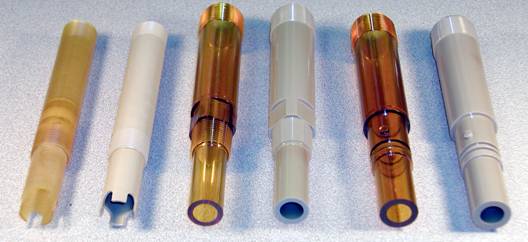

A plastic body housing material is available to suit any application from the mundane to the most difficult

Choosing the Correct pH/ORP Sensor

1. Choose a sensor body type that suits the physical parameters of the installation (refer to the Configurations Portion of pH/ORP and Ion Selective webpages). 2. Choose a sensor that suits the process application, temperature, chem istry, and physical parame ters of the installation (refer to Sensor Selection Guides and call factory or local sales agent for support) 3. Choose a sensor housing material that is compatible with the process chemistry, temperature & pressure (refer to Chemical Resistance Charts as posted under the Technical Documents portion of the website). 4. Select suitable temperature compensation element, solution ground & integrated preamplifier based upon the mating pH/ORP Instrument (refer to Electrochemical Instrumentation Page & ask for factory support). 5. Specify the required cable length based upon installation location (refer to Part Numbering Guide).

* Subject to application qualification and review by an approved ASTI sales agent and/or factory. Performance guarantee is posted on the ASTI online application questionnaire page. ** See list of supported pH/ORP/ISE Instruments webpages as posted on the ASTI website. *** Completion of Application Questionnaire form is required. Other restrictions may apply. |

||